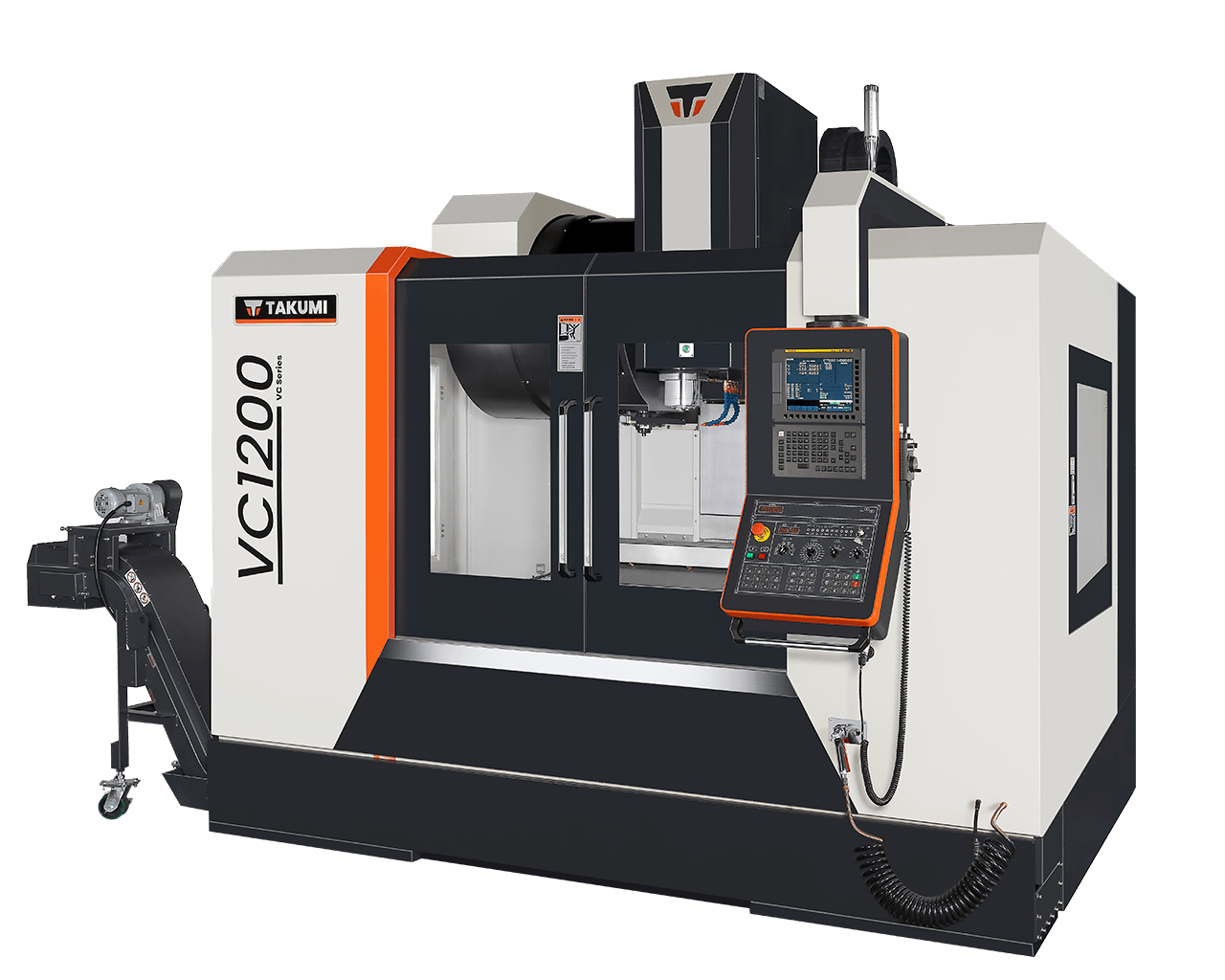

VC1200

Machine Information

Menu

Product Overview

3-Axis Vertical Machining Center

VC SERIES CNC Mill

High Efficiency Die/Mold Machining Center

Direct-Drive Spindle Technology

- Rapids of 1,417 inches per minute

- Perfect combination of fast cutting and high stability

- Designed and built for mold machining

- Pre-tensioned ballscrews minimize thermal growth and improve accuracy

- Ergonomic table simplifies setup

- Swiveling control panel optimizes floor space utilization

- Robust, precision-machined castings

- Hand-scraped contact areas

- 24-tool, CAT 40, swing-arm ATC standard

- Integrated washdown and chip management system

- Spindle chiller maximizes heat dissipation

- Direct-coupled ballscrews increase accuracy

- Absolute encoder ensures fast start-up

- FANUC© 0i-MF Series Control

- Fast, trained, factory service and support

Technical Specifications

| Travel |

|

|---|---|

| X-Axis | 50 in |

| Y-Axis | 25.98 in |

| Z-Axis | 24 in |

| Table |

|

| Table Size | 59 x 28.98 in |

| Table Max. Load | 2990 lbs |

| Spindle |

|

| Spindle Speed | 15000 rpm |

| Motor Power | 20.1 HP | 87.8 ft. lbs Motor Torque |

| Spindle Taper | Big Plus® CAT 40 |

| Feed Rate |

|

| Rapid Traverse (X/Y/Z) | 1417 x 1417 x 1417 ipm (36 x 36 x 36 m/min) |

| Cutting Feed Rate | 0.04 ~ 472.44 ipm (1 ~ 12 |

| ATC |

|

| Magazine Capacity | 30 Tools |

Information may change without notice. Optimum machine performance is reliant upon installation conditions at the facility, such as power supply, air supply, and ambient air conditions.

Standard Features & Options

Standard Features

- Roller Type Linear Guides on All Three Axes

- 15,000 RPM, CAT40 Big Plus Direct Drive Spindle

- Hand-scraped contact areas

- Fast 1,417 IPM Rapid Traverse Rate

- 4 IPM Milling Feed Rate

- 30 Station ATC – Random Access

- Work Light

- 3-Light Indicator Lamp

- Coolant Around Spindle

- Manual Pulse Generator (MPG)

- Spindle Thermal Chiller

- Programmable Coolant Wash Down System

- Programmable Cutting Air-blow

- Wash-Down Gun and Air gun

- Belt Type Chip Conveyor

- 30 bar Coolant-Through Spindle

- 4th Axis Preparation Wiring

- Takumi FANUC 0i “Plus” Control With 2 Years Parts and Labor Warranty

- 2 Mb Memory

- AICC II w/400 Block Look Ahead

- Rigid Tapping (M29)

- FANUC Set-Up Guidance

- Compact Flash Port; USB Port; Ethernet Port

- Manual Guide i

- 2 Years Parts, 1 Year Labor Warranty

- Leveling Bolts and Pads

- Operator Manuals

Optional Accessories

- 1 Gigabyte Data Server

- 4th axis rotary table

- BT 40 tool holder conversion

- Collant filtration

- Coolant through spindle (CTS)

- Lift up chip conveyor with cart

- Memory card editing

- Oil mist collector

- Oil mist device

- Oil skimmer

- Part probe measurement system

- Tool probe measurement system

Related Video

https://www.youtube.com/watch?v=AV065qzuGHY